630PE pipe production line

1、 Usage conditions

1. Power supply: three-phase 380V, 50HZ

2. Environment: Indoor non hazardous area, humidity within 85%, no condensation, temperature 0-30 ℃; Below 25 ℃

Cooling water, water pressure above 0.3MPa; Compressed air pressure above 0.5MPa.

3. Total length of production line: approximately 60 meters

2、 General Principles of Production Line

1. Equipment raw material: HDPE granular material

2. Production line speed: 0.1-1.0m/min

3. Extrusion center height: 1100mm

4. Operation direction: from right to left

5. Equipment color: Standard color (if other colors are required, the purchaser shall provide color codes)

三、Equipment composition

order number | Device Name | specifications | quantity | remarks |

1 | Automatic feeding machine | ZJ900 | 1 tower |

|

2 | Hopper dryer | STG-U | 1 tower |

|

3 | Single screw extruder | SJ120/33 | 1 tower |

|

4 | Single screw extruder | SJ25/25 | 1 tower |

|

5 | Vacuum sizing box | ZK-630 | 1 tower |

|

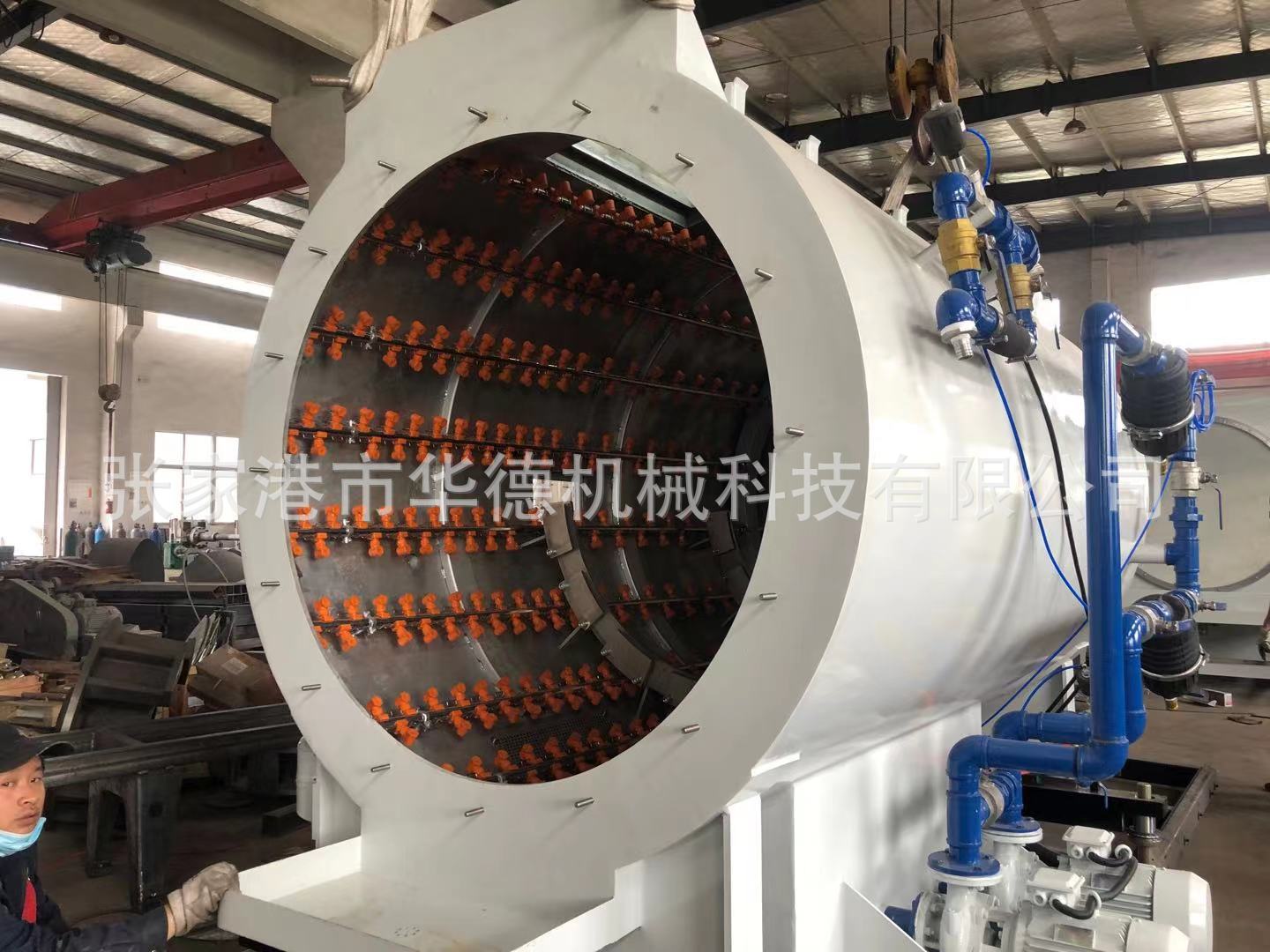

6 | Spray water tank | ZK-630 | 2 tower |

|

7 | Six claw traction machine | QY-630 | 1 tower |

|

8 | Chip free cutting machine | XQG-630 | 1 tower |

|

9 | Flipping rack | FL-630 | 1 tower |

|

Some customers require a three-layer co extrusion configuration sheet to be provided separately | ||||